The Importance Of Precision Tooling In Modern Manufacturing

In today's fast-paced and competitive manufacturing industry, precision tooling plays a crucial role in ensuring efficiency, accuracy, and cost-effectiveness. In this article, we will delve into the importance of precision tooling in modern manufacturing and explore how it impacts product quality, production timelines, and overall business success. Join us as we uncover the key benefits and applications of precision tooling in shaping the future of manufacturing processes.

- Understanding the Role of Precision Tooling in the Manufacturing Process

Precision tooling plays a crucial role in the modern manufacturing process, providing the necessary tools and equipment to ensure efficiency, accuracy, and quality in the production of various goods. In this article, we will delve into the significance of precision tooling in manufacturing, highlighting its importance and the role it plays in various industries.

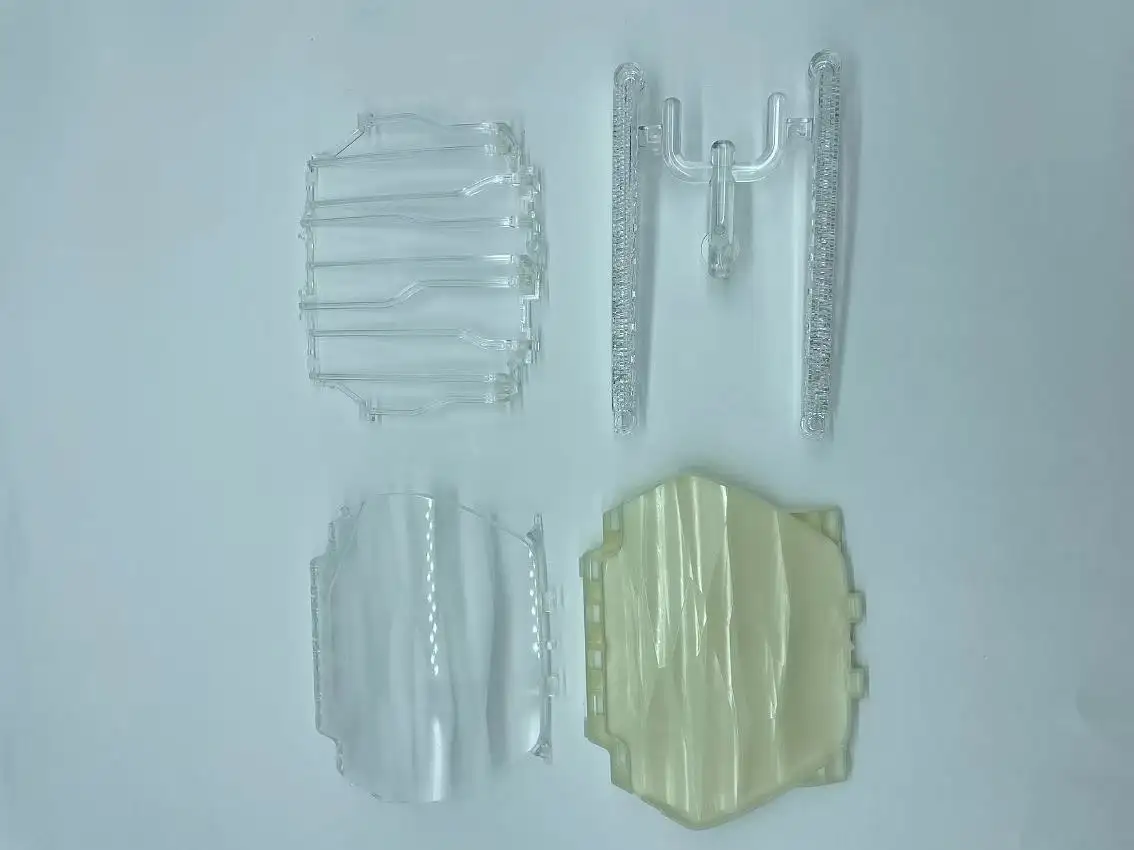

Precision tooling refers to the specialized tools and equipment used in manufacturing processes to produce precise and accurate components. These tools are specially designed and engineered to meet specific requirements, ensuring that the final product meets the required standards and specifications. Precision tooling encompasses a wide range of tools, including cutting tools, molds, dies, jigs, fixtures, and gauges, among others.

One of the key benefits of precision tooling in manufacturing is its ability to improve efficiency and productivity. By using precision tools, manufacturers can produce components faster and with higher precision, reducing the need for rework and minimizing waste. This not only saves time and resources but also improves overall production output, allowing companies to meet customer demand more effectively.

In addition to improving efficiency, precision tooling also plays a crucial role in ensuring quality and consistency in manufacturing. By using precise tools and equipment, manufacturers can maintain tight tolerances and produce components that meet the required specifications. This ensures that the final product is of high quality, free from defects, and meets customer expectations. Precision tooling also helps in reducing variability and improving repeatability, resulting in consistent product quality and performance.

Furthermore, precision tooling enables manufacturers to innovate and develop new products more effectively. With the use of advanced technologies and precision tools, manufacturers can push the boundaries of design and engineering, creating new and innovative products that meet the evolving needs of customers. Precision tooling also allows for the production of complex components and intricate designs, enabling companies to differentiate themselves in the market and stay ahead of the competition.

Precision tooling is essential in a wide range of industries, including aerospace, automotive, electronics, medical, and consumer goods. In the aerospace industry, precision tooling is used to manufacture aircraft components with tight tolerances and high precision. In the automotive industry, precision tooling is essential for producing engine parts, body components, and other critical components. In the electronics industry, precision tooling is used to manufacture circuit boards, microchips, and other electronic components. In the medical industry, precision tooling is crucial for producing medical devices, implants, and surgical instruments. In the consumer goods industry, precision tooling is used to manufacture a wide range of products, including appliances, furniture, and toys.

In conclusion, precision tooling is a vital part of the modern manufacturing process, enabling companies to produce high-quality products efficiently and effectively. By investing in precision tooling and embracing advanced technologies, manufacturers can improve efficiency, quality, and innovation, driving growth and success in today's competitive market.

- Advantages of Utilizing Precision Tooling for Increased Efficiency

Precision tooling plays a crucial role in modern manufacturing processes, offering a wide range of advantages that ultimately lead to increased efficiency and productivity. From improving product quality to reducing waste and optimizing production timelines, precision tooling is a valuable asset for manufacturers looking to stay competitive in today's fast-paced market.

One of the key advantages of utilizing precision tooling is the ability to achieve unparalleled levels of accuracy in manufacturing processes. Precision tools are designed to exact specifications, ensuring that each component is produced with the highest level of precision possible. This level of accuracy is essential for industries such as aerospace and automotive, where even the slightest deviation can result in costly errors or product failures.

In addition to accuracy, precision tooling also plays a critical role in improving product quality. By using precision tools, manufacturers can ensure that each component meets the required specifications, leading to higher quality products that are more reliable and durable. This, in turn, can help companies build a strong reputation for quality and reliability, attracting more customers and driving business growth.

Another key benefit of precision tooling is the ability to reduce waste and minimize production costs. Precision tools are designed to maximize efficiency and minimize waste, resulting in lower raw material costs and reduced scrap rates. By streamlining production processes and improving material utilization, manufacturers can increase their profitability and remain competitive in a crowded marketplace.

Furthermore, precision tooling can help optimize production timelines and increase overall efficiency. With precision tools, manufacturers can reduce production times, improve workflow processes, and meet tight deadlines without sacrificing quality. This allows companies to take on more projects, increase their output, and ultimately grow their business.

Overall, the importance of precision tooling in modern manufacturing cannot be overstated. By investing in precision tools and technologies, manufacturers can reap a wide range of benefits, including increased accuracy, improved product quality, reduced waste, and optimized production timelines. These advantages can ultimately lead to greater efficiency, profitability, and success in today's competitive market.

- Ensuring Quality Control with Precision Tooling in Manufacturing

In modern manufacturing, precision tooling plays a crucial role in ensuring quality control throughout the production process. From automotive to aerospace industries, precision tooling is utilized to create complex components with the utmost accuracy and precision. This article explores the importance of precision tooling in modern manufacturing and how it helps to maintain high standards of quality control.

Precision tooling refers to the use of specialized tools and equipment to manufacture components with tight tolerances and exact specifications. These tools are vital in achieving consistent results and minimizing errors during the manufacturing process. Precision tooling includes a wide range of equipment such as CNC machines, cutting tools, and measuring instruments, all designed to provide precise control over the manufacturing process.

One of the key benefits of precision tooling in modern manufacturing is the ability to maintain high levels of quality control. By using precise tools and equipment, manufacturers can ensure that each component is manufactured to the exact specifications required. This helps to minimize defects and waste, resulting in a higher overall quality of the final product. With precision tooling, manufacturers can also create components with complex geometries and intricate details that would be impossible to achieve with conventional methods.

Another advantage of precision tooling in modern manufacturing is the ability to increase efficiency and productivity. By using advanced tools and equipment, manufacturers can automate many aspects of the production process, reducing the need for manual labor and streamlining operations. This results in shorter lead times, lower production costs, and increased output, ultimately leading to improved profitability for manufacturing companies.

Furthermore, precision tooling allows manufacturers to stay competitive in today's fast-paced market. As technology continues to advance, the demand for high-quality, precision-engineered components is only increasing. By investing in precision tooling, manufacturers can meet these demands and stay ahead of the competition. Companies that fail to adopt precision tooling risk falling behind and losing market share to more innovative and efficient competitors.

In conclusion, precision tooling plays a vital role in modern manufacturing by ensuring quality control, increasing efficiency, and staying competitive in today's market. By investing in advanced tools and equipment, manufacturers can create high-quality components with tight tolerances and complex geometries. With precision tooling, companies can achieve consistent results, minimize errors, and ultimately deliver superior products to their customers. As technology continues to evolve, precision tooling will remain a cornerstone of modern manufacturing, driving innovation and pushing the boundaries of what is possible in the industry.

- Impact of Precision Tooling on Productivity and Cost-effectiveness

Precision tooling plays a crucial role in modern manufacturing processes, significantly impacting productivity and cost-effectiveness. In today's highly competitive global market, manufacturers are constantly seeking ways to improve efficiency and reduce production costs. Precision tooling is a key factor in achieving these objectives, as it ensures the accurate and consistent production of high-quality parts and components.

One of the primary advantages of precision tooling is its ability to reduce waste and enhance productivity. By using precisely machined tools and dies, manufacturers can minimize material wastage and optimize the production process. This results in higher output levels, shorter production times, and increased efficiency. Additionally, precision tooling allows for the automation of manufacturing processes, further improving productivity and reducing the need for manual labor.

In terms of cost-effectiveness, precision tooling plays a vital role in reducing manufacturing costs. The use of high-precision tools and dies helps to minimize errors and defects in the production process, resulting in lower scrap rates and rework costs. Furthermore, precision tooling enables manufacturers to achieve tighter tolerances and greater consistency in their products, reducing the risk of costly recalls or warranty claims. Overall, investing in precision tooling can lead to significant cost savings over time.

Another important aspect of precision tooling is its impact on product quality. By using accurately machined tools and dies, manufacturers can achieve precise and uniform results, ensuring the reliability and performance of their products. This is particularly crucial in industries such as aerospace, automotive, and electronics, where even minor deviations can have serious consequences. With precision tooling, manufacturers can maintain strict quality standards and meet the demanding requirements of their customers.

Moreover, precision tooling offers flexibility and versatility in manufacturing processes. By using customized tooling solutions, manufacturers can adapt to changing market demands and develop new products quickly and efficiently. This agility is essential in today's fast-paced business environment, where companies must constantly innovate and differentiate themselves from competitors. Precision tooling provides the foundation for this innovation, enabling manufacturers to explore new opportunities and expand their product offerings.

In conclusion, the importance of precision tooling in modern manufacturing cannot be overstated. From improving productivity and cost-effectiveness to ensuring product quality and flexibility, precision tooling is essential for manufacturers to stay competitive in today's market. By investing in high-quality tools and dies, companies can optimize their production processes, enhance their product offerings, and ultimately drive growth and profitability. As technology continues to advance, precision tooling will only become more critical in shaping the future of manufacturing.

- Investing in Cutting-edge Precision Tooling Technology for Competitive Edge

In today's fast-paced manufacturing industry, precision tooling plays a crucial role in ensuring the quality and efficiency of production processes. With the advancement of technology, investing in cutting-edge precision tooling has become increasingly important for companies looking to gain a competitive edge in the market.

Precision tooling refers to the process of designing and manufacturing tools with tight tolerances and high accuracy, allowing for precise shaping and machining of materials. These tools are essential for a wide range of industries, including automotive, aerospace, electronics, and medical devices, where precision and quality are of utmost importance.

One of the key benefits of precision tooling is its ability to optimize manufacturing processes, resulting in higher productivity and lower production costs. By using precision tools, manufacturers can reduce waste, improve cycle times, and enhance the overall quality of their products. This, in turn, can give companies a competitive edge by allowing them to deliver products faster and more efficiently than their competitors.

Furthermore, investing in cutting-edge precision tooling technology can also lead to innovation and product development. By incorporating advanced tools and techniques into their manufacturing processes, companies can stay ahead of the curve and meet the evolving demands of the market. For example, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for the creation of highly complex and intricate components that would be impossible to produce with traditional methods.

In addition, precision tooling can also improve the safety and reliability of manufacturing operations. By using high-precision tools, companies can minimize the risk of defects and errors, leading to safer working environments and fewer disruptions in production. This not only benefits the employees but also ensures that customers receive products of the highest quality.

Overall, the importance of precision tooling in modern manufacturing cannot be overstated. Companies that invest in cutting-edge technologies and techniques for precision tooling stand to gain a significant competitive advantage in today's market. By optimizing production processes, driving innovation, and improving product quality, precision tooling can help companies stay ahead of the competition and achieve long-term success in the industry.

Conclusion

In conclusion, as highlighted throughout this article, precision tooling plays a crucial role in modern manufacturing processes. The ability to produce high-quality, precise components is essential for maintaining efficiency, reducing waste, and achieving optimal product performance. With 30 years of experience in the industry, our company understands the importance of investing in top-of-the-line precision tooling equipment and skilled technicians to consistently deliver exceptional results. By prioritizing precision tooling in our manufacturing practices, we not only ensure the success of our products but also contribute to the advancement of the manufacturing industry as a whole.