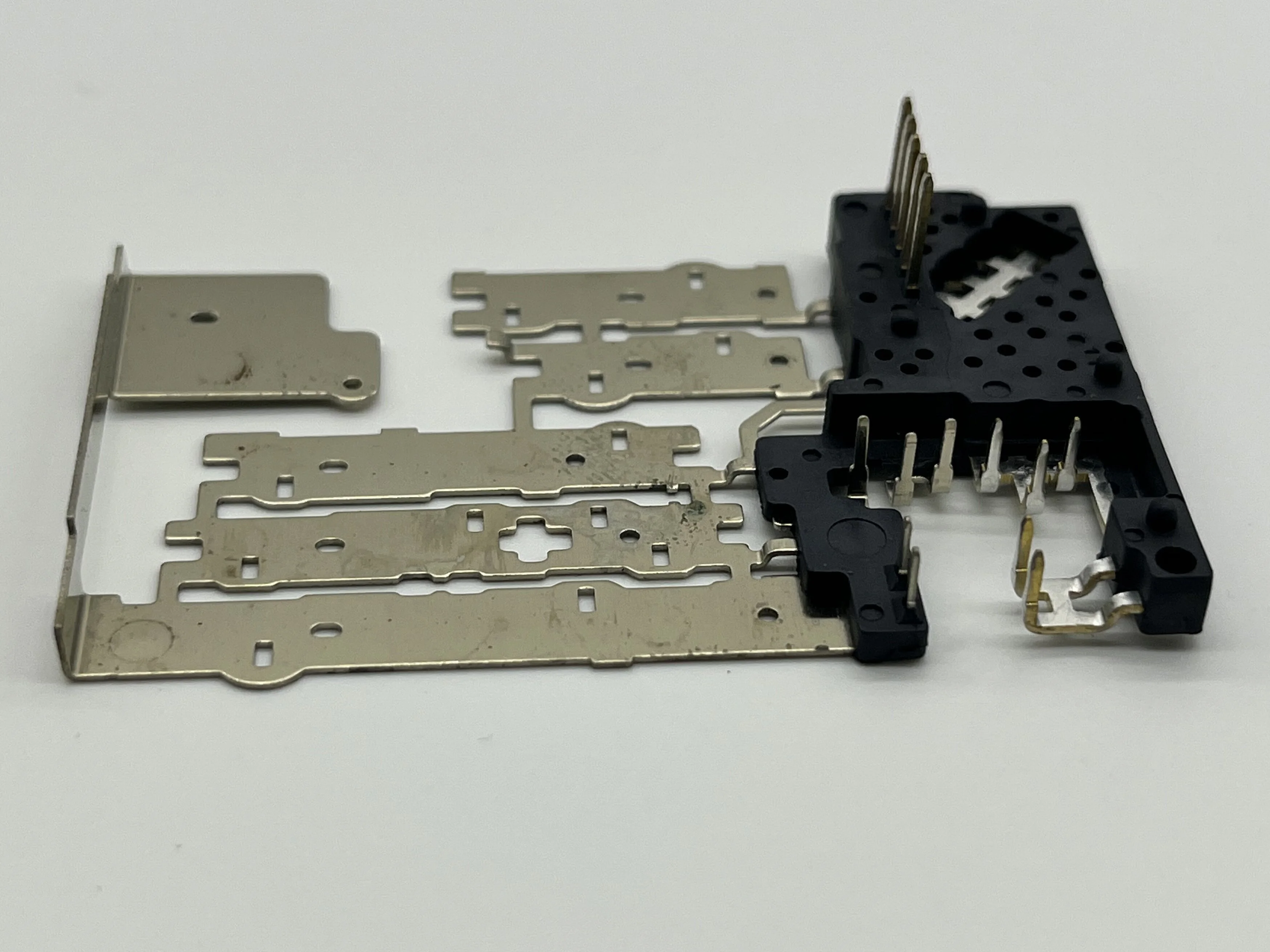

Precision Automobile Plastic Components with Injection Tooling and Overmold Solutions

This product features a complexity rate of ★★★★, indicating a high level of intricacy in design and manufacturing. The material used is PPS+GF40 (Polyphenylene Sulfide with 40% Glass Fiber), enhanced with UV stabilization, ensuring excellent durability and resistance to ultraviolet light. Additionally, the product incorporates Xenoy CL100, known for its toughness and resistance to chemicals and impact, making it suitable for demanding environments.

The mold type employed is overmold, a technique that allows for the combination of multiple materials into a single part, providing improved functionality and structural integrity. This combination of advanced materials and sophisticated molding processes ensures a high-performance product, ideal for applications requiring strength, stability, and environmental resistance.

Pioneer Plastech

What is Overmold?

Overmold is an injection molding process used to create a product by combining two or more materials, typically a rigid substrate (base material) and a softer, more flexible overmold material. This process enhances the functionality, aesthetics, and ergonomics of the final product.

Overmolding is a versatile process used across various industries to create products that are both functional and visually appealing, offering enhanced user experience through the combination of different material properties.

Product Specifications

| Name | INSERT BLOCK |

| Material | >PPS+GF40< UV Stabilized-Xenoy CL100 |

| Material Composition | Polyphenylene Sulfide;Glass Fiber 40% |

| Complexity Level | ⭐⭐⭐⭐ |

| Molding | Overmolding |

| Application | Automotive |

| Trait |

Stable with prolonged exposure to sunlight. Ideal for outdoor applications. High impact resistance, chemical resistance, and robust mechanical properties, suitable for harsh environments |