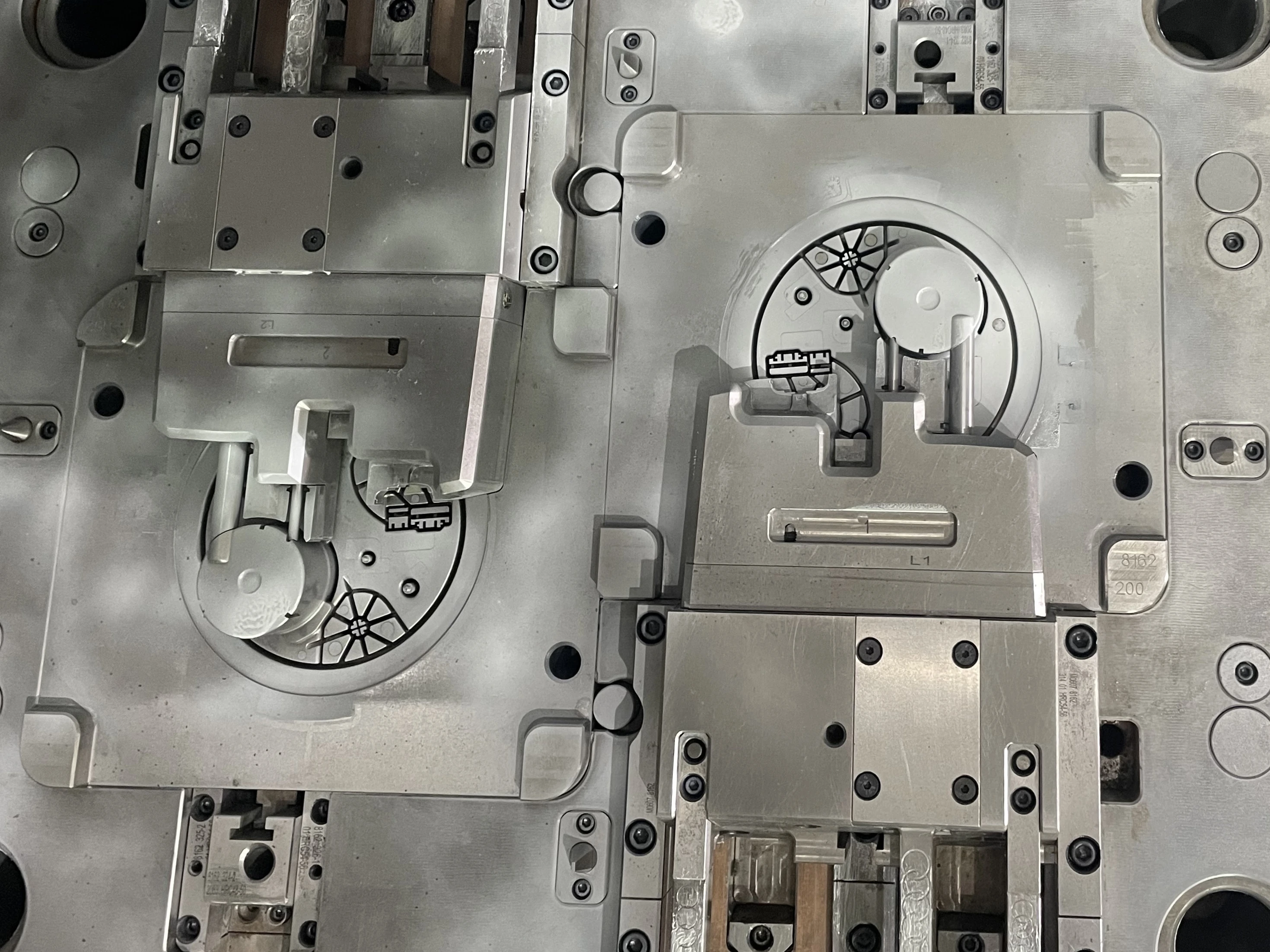

‘Lifter in Slider’ Example

Overview

PIONEER is able to produce a series of housings characterised with 'lifer in slider' techniques.

When a lifter is incorporated into a slider, it creates a more complex mechanism to handle internal and external undercuts, or parts with side cores and vertical movements.

The lifter's angle, the timing of the slider movement, and other parameters are fine-tuned to achieve smooth and efficient operation. This ensures that the part is released properly without damaging any features or causing excessive wear on the mold.

What Are Lifters and Sliders?

Lifters are specialized features in mold design that enable the ejection of complex parts with undercuts, ensuring smooth and precise movement. Sliders, on the other hand, are crucial for managing side actions and guiding parts during ejection. Together, they facilitate the production of intricate geometries that would be impossible with standard mold designs.

Why [lifter in slider]?

-

Enhanced Part Quality: By effectively managing undercuts and side actions, lifters and sliders help produce parts with better dimensional accuracy and surface finish.

-

Increased Production Efficiency: These components reduce cycle times and improve mold operation, allowing for faster production rates without compromising quality.

-

Design Flexibility: Lifters and sliders provide the flexibility needed to create complex designs, catering to a wide range of industries, from automotive to consumer goods.

-

Durability and Reliability: Designed for longevity, high-quality lifters and sliders ensure consistent performance over time, minimizing downtime and maintenance costs.

Partner with PIONEER PLASTECH

Incorporating lifters and sliders into your injection mold design can revolutionize your production process. Experience the benefits of enhanced quality, efficiency, and design freedom. Partner with us to explore advanced solutions tailored to your specific needs!