Precision Tooling for Automotive Injection Molding in Advanced Automotive Lighting Systems

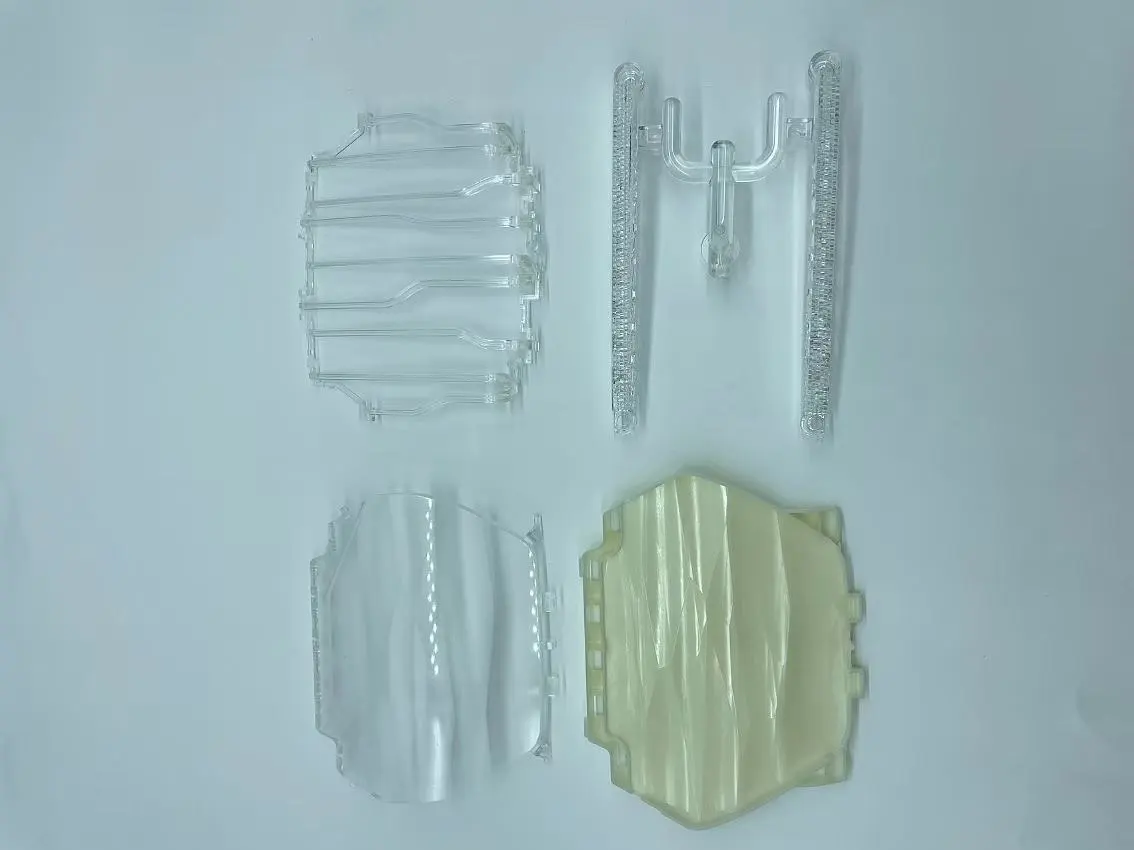

Our molds are expertly crafted to produce a wide range of plastic components essential for modern automotive lighting systems. These include headlight and taillight housings, reflectors, lenses, and LED holders, all of which demand exceptional precision, clarity, and heat resistance. These components not only ensure the functionality of lighting systems but also play a significant role in a vehicle's aesthetic and safety features.

Through advanced molding techniques, we deliver components with high-definition details, ensuring seamless integration into various lighting system designs. The molds accommodate customizable features such as unique geometries, improved light diffusion, and anti-glare properties. This allows automakers to achieve cutting-edge lighting designs that enhance visibility while adhering to safety regulations.

Additionally, materials used in these components are engineered to withstand heat generated by powerful lighting systems, UV exposure, and environmental wear, ensuring long-lasting performance. Our plastic components support energy-efficient lighting technologies such as LEDs, aligning with the industry's shift towards sustainability. By blending functionality, durability, and design versatility, our solutions empower manufacturers to create lighting systems that enhance both the safety and visual appeal of their vehicles.