Optimizing Plastic Injection Mold Design for Automotive Parts with Gate Insert

Enhancing Automotive Part Production Efficiency with Gate Insert in Plastic Injection Molding

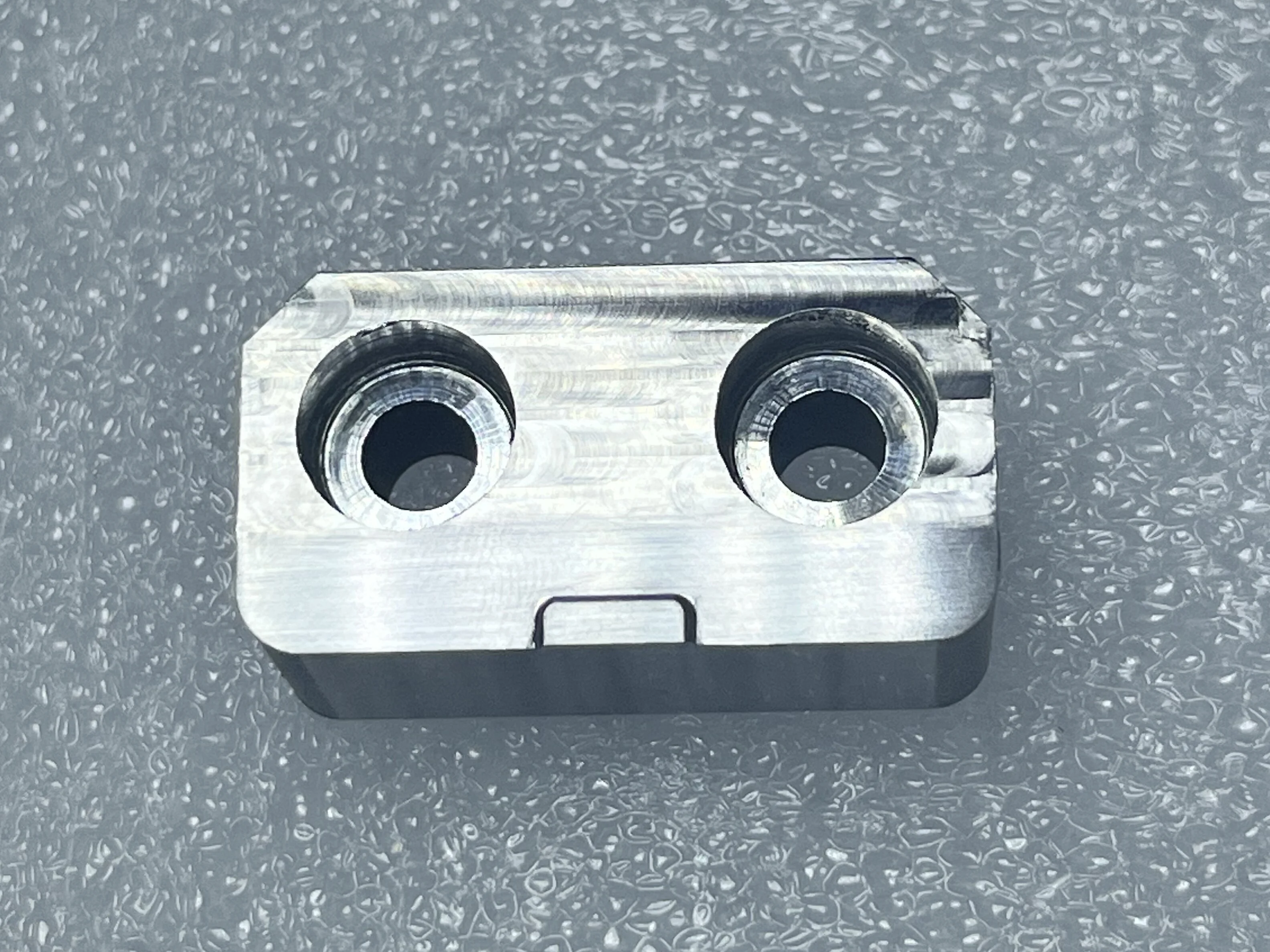

The gate insert, made from GS344ESR material, is a smart and practical design solution for production molds, particularly in high-volume manufacturing. Over time, the gate area of a mold is subject to wear due to the high injection pressures and friction caused by the flow of plastic. By incorporating a gate insert, manufacturers can address this issue effectively. The gate insert acts as a replaceable component, allowing the worn insert to be swapped out with a new one when necessary, without the need to replace the entire mold. This design not only extends the life of the mold but also reduces maintenance costs and downtime, making it an ideal solution for long-term production runs.

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Contacts

General Manager: Nixon Kuang

Phone: +86 139 2508 7514

Email: Nixon.kuang@pioneerplastic.com

Address: No.5. the 2nd Jingye Rd Yanchuan Community Yanluo Street Bao'an District Shenzhen, China PC 518105

Copyright © 2025 Pioneer Plastech (Shenzhen) Ltd. | Privacy Policy Sitemap