Advanced Electrical and Electronic Plastic Components with Injection Tooling Precision

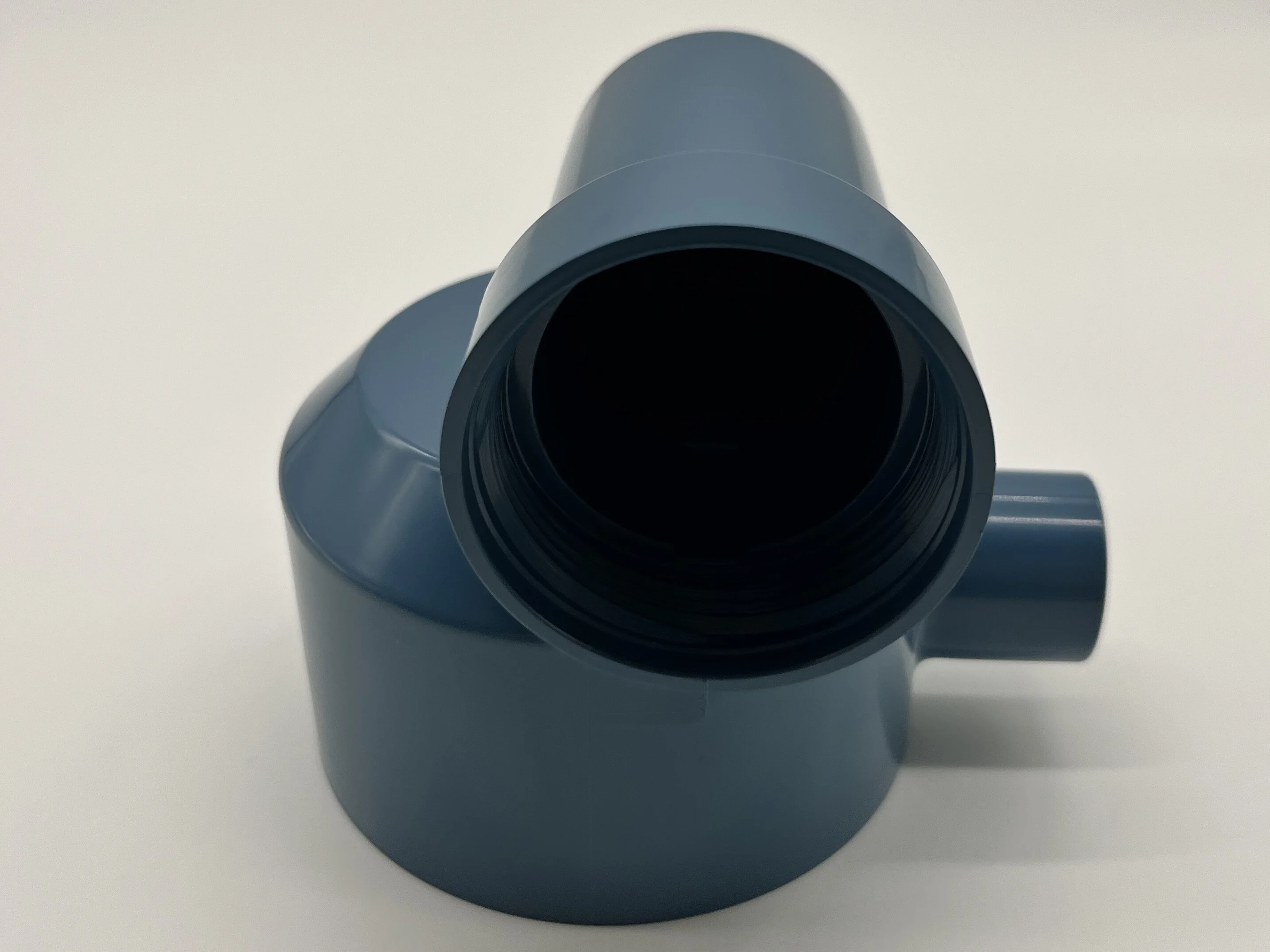

The ELECTRONIC HOUSING is designed with a complexity rate of ★★★★, reflecting a high level of intricacy and precision in its construction. It is manufactured using SABIC VALOX V3900WX, a blend of PC (Polycarbonate) and PBT (Polybutylene Terephthalate). This material offers excellent mechanical strength, dimensional stability, and resistance to heat and chemicals, making it ideal for electronic applications.

Key features include:

- Cav: 1 (produced in a single-cavity mold, ensuring high-quality and detailed production).

- Trait: Threaded, providing secure and reliable assembly, which is essential for housing electronic components.

This housing is engineered to meet the stringent requirements of the electronics industry, offering durability, precision, and enhanced performance for a variety of electronic devices.

Pioneer Plastech

How to demold products with internal threads?A

1. Rotational Demolding

Utilize a rotational demolding mechanism, where mechanical devices (such as unscrewing screws) or a motor drive rotate the product, allowing it to unscrew from the mold.

2. Segmented Threads

Design a segmented thread core in the mold, where the threaded sections retract separately during mold opening, preventing thread damage.

3. Slide Mechanism

Incorporate slides or angled lifters in the mold that move laterally when the mold opens, releasing the threads from the product.

4. Flexible Materials

For simpler or shallow threads, use a flexible core (like rubber or an elastic material) that compresses during mold opening, allowing easy thread release.

5. Manual Unscrewing

For complex or low-volume production, manual unscrewing can be employed, where the product is rotated manually or with tools to release it from the mold.

Product Specifications

| Name | ELECTRONIC HOUSING |

| Material | SABIC VALOX V3900WX (PC/PBT) |

| Material Property | Excellent Impact Resistance |

| Complexity Level | ⭐⭐⭐ |

| Molding | 2 plate, 1 cav, threaded insert, |

| Application | Electrical and Electronic |

| Special Production Process |

Annealing |

| Annealing |

The purpose of annealing plastic products is to reduce internal stresses, improve dimensional stability, enhance mechanical properties, and prevent warping or deformation. |