Precision Automobile Plastic Components with Injection Mold and Thermal Compression Solutions

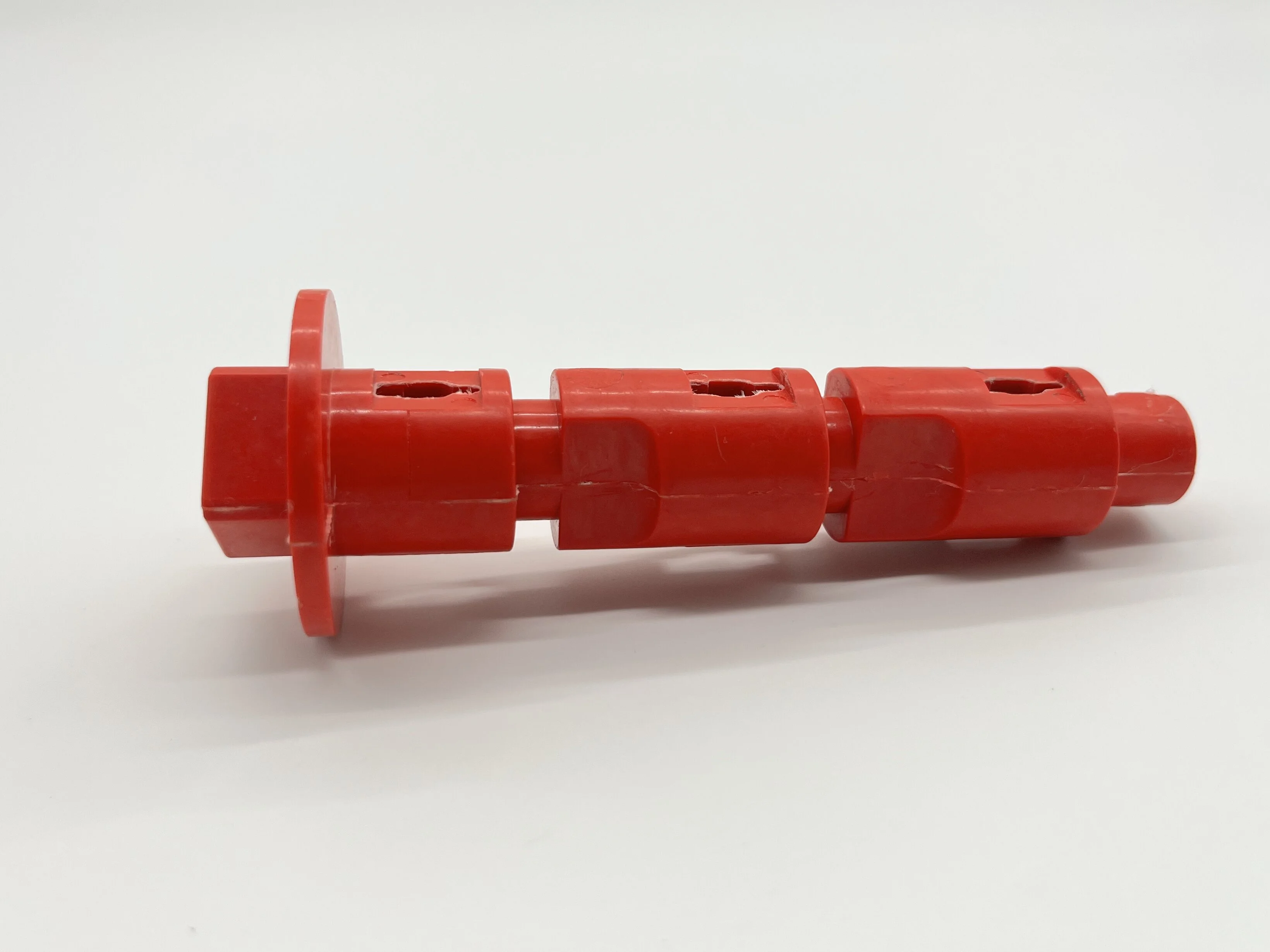

The ROTOR, 400/600A - dedicated 3P is designed with a complexity rate of ★★★★, reflecting its intricate design and production requirements. This component is produced using thermal compression molding, a process that ensures durability and high performance.

Key specifications include:

- Cav: 8 (manufactured in an eight-cavity mold for efficient production).

- Color: Red, using IDI SMC E206 - Red, a Sheet Molding Compound known for its strength, heat resistance, and consistent color.

- Difficulties: The process involves challenges such as flash cutting, which requires precision to maintain the component's integrity and appearance.

This rotor is engineered to meet the rigorous demands of electrical applications, offering reliability and precision in performance while maintaining a high-quality finish.

Pioneer Plastech

What is IDI SMC E206 - Red ?

IDI SMC E206 - Red is a Sheet Molding Compound (SMC) material, commonly used in high-performance composite manufacturing. Here's a detailed analysis of the material:

Material Type

- SMC (Sheet Molding Compound) is a reinforced composite material made from a polymer matrix typically reinforced with chopped glass fibers. It is molded into complex shapes through heat and pressure, providing high-strength and durable components.

Key Components

Polyester Resin:

- The base material is typically unsaturated polyester resin, offering chemical resistance and binding properties.

Glass Fibers:

- Reinforcement comes from chopped glass fibers, which enhance the strength, rigidity, and impact resistance of the material.

Fillers:

- May include fillers like calcium carbonate or other minerals to improve hardness and dimensional stability.

Pigments:

Red pigment is added to give the material its characteristic red color.

Typical Applications

- Automotive Industry: Used for manufacturing car body panels, bumpers, and door panels due to its strength and durability.

- Electrical and Electronics: Suitable for insulating components, switch panels, and other electrical parts.

- Construction Industry: Applied in building exterior panels, roofing components, and other weather-resistant structures.

Product Specifications

| Name | ROTOR, 400/600A - dedicated 3P |

| Material | IDI SMC E206 - Red |

| Material Property |

High Strength and Rigidity The glass fiber reinforcement provides exceptional mechanical strength and stiffness, making it suitable for demanding applications. |

| Complexity Level | ⭐⭐⭐⭐ |

| Molding | Thermal Compression Molding |

| Application | Automotive |